Powertrain Vehicle Integration

The integration of the powertrain and vehicle includes following steps:

- Vehicle simulation and powertrain integration

- Inspection, assembly and preparation of vehicle

- Vehicle validation test

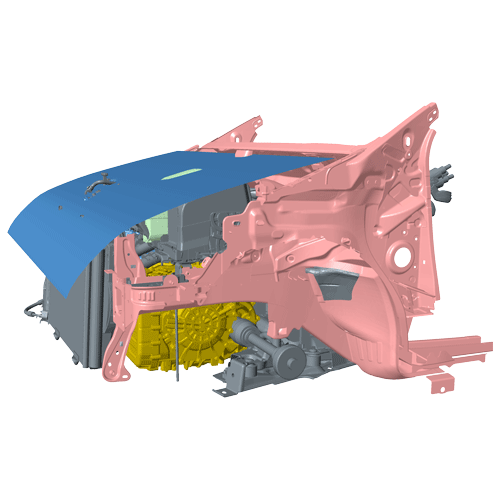

Vehicle Simulation and Powertrain Integration

Powertrain integration is a multilateral activity including packaging of the powertrain in the engine bay, cost-effective modifications to integration systems, selection of Front End Accessory Drive (FEAD) components considering safety requirements that are conducted with the help of 3D modeling software, in-house standards and development procedures. Vehicle dynamic requirements from powertrain such as fuel consumption, traction, acceleration and more detailed item like gear ratio will be investigated, using dynamic simulation software to determine possibilities and limitations. These results are presented to managers and potential clients for planning and investment in the form of strategic reports.

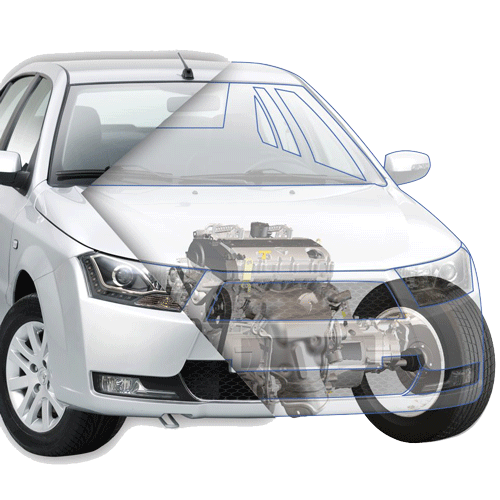

Vehicle Validation Tests

IPCO testing experts’ consistency and years of experience in context of compliance with relevant automotive standards and the use of specialized and valid measuring instruments, offer efficient powertrain test services. Measurement of the powertrain variables such as fuel consumption, emission, drivability, vehicle performance (hill start, acceleration) and determination of coast down coefficient of different vehicles are performing in different climatic conditions.

Inspection, Assembly and Preparation

Vehicle preparation is performed for signing off the testing vehicle before emission, durability, performance, drivability tests during development and also preparation for conformity of production. IPCO Company provides assembly services, physical packaging, prototyping components and troubleshooting having experienced technical staff and various workshops using special equipment for vehicles with diesel, gasoline, Bi-fuel and hybrid powertrains.